| Home | SourceForge.net | More documentation |

| Project Page |

| Documentation |

| Download |

| Installation Info |

| Tickets |

| Public forums |

Warehouse management

This application was developed in a few months thanks to Openswing capabilities: this development framework allows to create RIAs with a GUI having very complex contents with low development time.

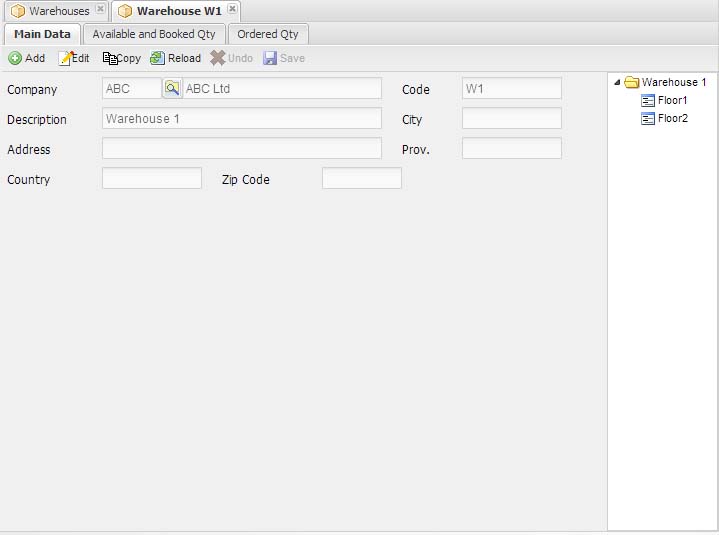

JAllInOneWeb allows to define a set of warehouses, each warehouse is optionally composed of bins. A bin can contains good items and damaged items. Optionally serial numbers anc bar codes support are provided per item: this assures compliance with the tracking needs.

Warehouse management process allows the inventory in the specified organization (per company) to always be up to date and correctly valued, because of item quantities availabilities in warehouses are always up to date, according to warehouse movements (managed in several ways: manually, by delivery notes, etc).

The warehouse structure of the organization (per company) can be defined at the unit level (bins), in a hierarchical way: this facilitates the exact localization of stocks at any time.

All items have a measure unit, expressed in the item definition: stocks are expressed in warehouses according to that measure and item quantities reported in entry inwards (expressed with supplier measure are automatically converted with the warehouse item measure unit.

|

Warehouse form provides saveral enquiry criteria:

- Search available/damaged items and their quantities per bin, by warehouse hiearchy navigation (and optionally filtered by a specific item)

- Search booked and available quantities per item

- Search ordered quantities per item

Other features include:

- Manual item movements

- Warehouse motives definition

- Warehouse movements enquiry

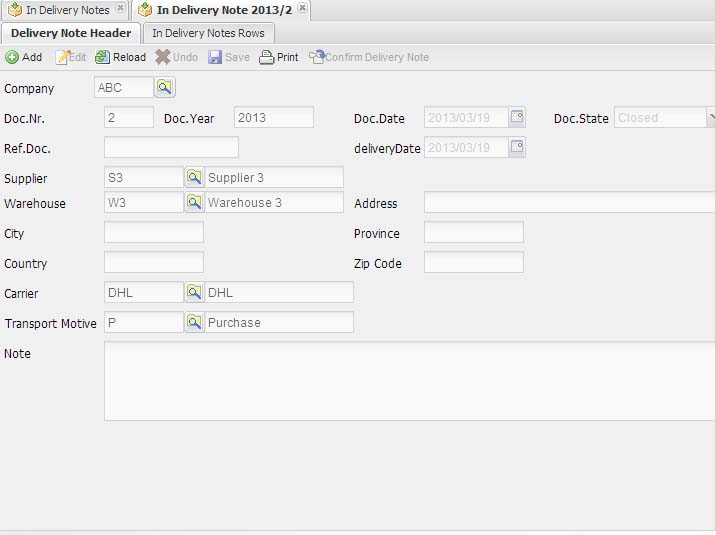

Entry inwards management allows to create delivery notes in two ways: manually or by specifing a purchase order already confirmed: you can quickly import order lines (some lines or all), so it is possible to define more delivery notes for the same purchase order.

Once a delivery note has been confirmed the specified warehouse is automatically updated, by creating warehouse movements that update item quantities: in this way item availabilities in warehouses are always up to date.

A report is available to print the delivery note.

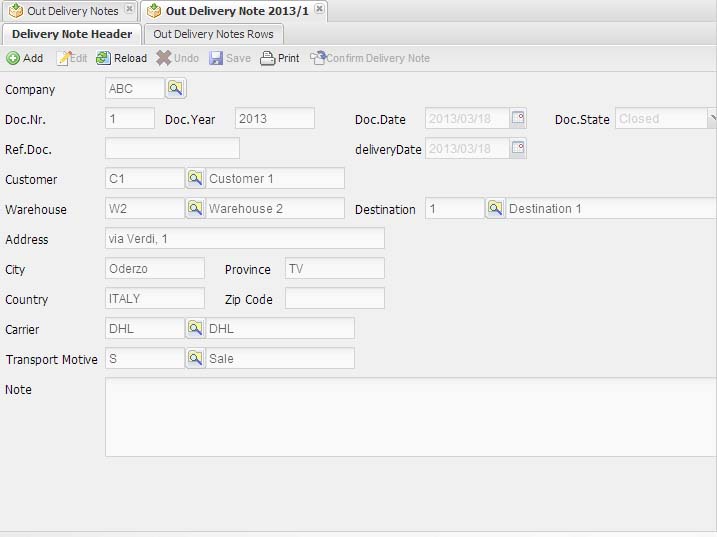

Out delivery notes management allows to create delivery notes starting from one or more delivery requests, that are automatically created when a sale order/contract is confirmed. A delivery request is created for each delivery date reported in item rows of the sale document, so items are grouped and distributed according to their delivery date in one or more delivery requests.

|

A user can quickly import delivery request's lines (some lines or all), so it is possible to define more delivery notes for the same selling document (for its delivery requests) or a single delivery note can include many delivery requests, related to many orders/contracts. The order tracking feature allows to collect all this links and show the realation among documents in a simple way.

|

Once a delivery note has been confirmed the specified warehouse is automatically updated, by creating warehouse movements that update item quantities: in this way item availabilities in warehouses are always up to date. Also item out quantities is delivery requests and sale documents are updated in this time and a delivery request is automatically closed when all items it refers have been processed in some out delivery note.

Retail sales automatically update warehouse quantities when confirming them, without requiring delivery note definition.

A report is available to print the delivery note.

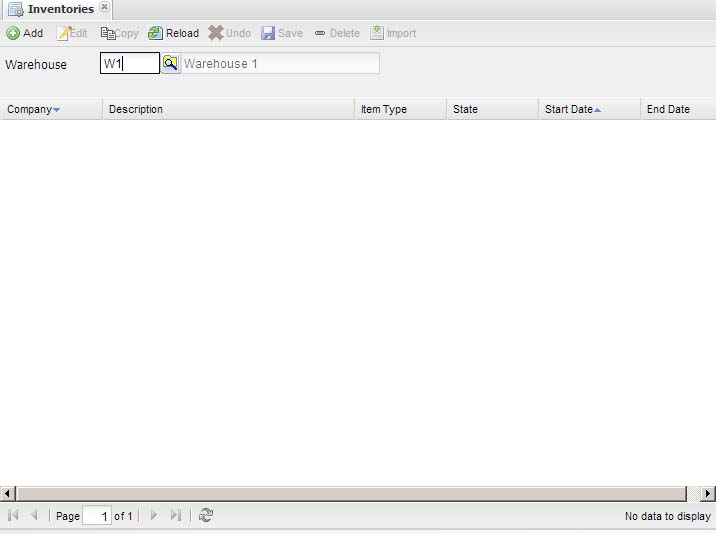

Warehouse inventory include two main features:

- Show inventory per company (and optionally per warehouse too) - a report in PDF format, reporting current items availabilities

- Inventories definition - a list of inventories, each one can include a specific list of items and related availabilities, used to compare these quantities with real quantities and generate correction movements in warehouse.

Inventories list allows to define one or more inventories.

|

When creating a new inventory, the filter panel must be fully filled: a company, a wareouse and good/damaged items type must be defined, otherwise the inventory creation cannot be performed.

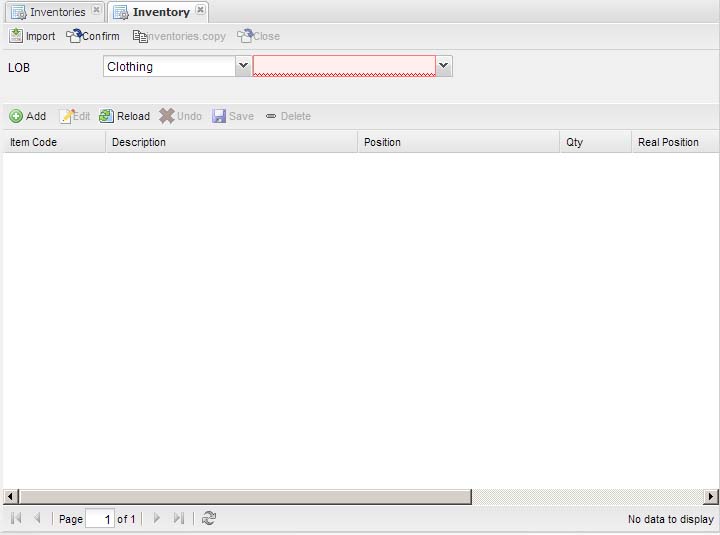

An inventory has a description and a state: initially an inventory is in open state; in that state the use can double click on an inventory and open the inventory detail window, used to define the list of items to manage within the current inventory.

|

Items can be defined manually, by inserting an item per time (only items without variants are allowed when inserting them manually).

Items can be defined using "Import button: the filter panel can be used to filter the amount to items to import, in order to import only a specific item type (using only the item type combo box) or a specific path in the item hierarchy of the selected item type. Multiple imports can be performed, using different hierarchy paths.

Import task is asynchronous and it only includes in the inventory the items that match the filtering condtions and having an availability amount different to zero in the specified warehouse.

After items import task, the user can confirm all items and move the inventory state to confirmed: after this transition, no more items can be imported and no warehouse movement is allowed in the whole application for all items included in the inventory, until (i) the inventory is deleted or (ii) the inventory is closed.

In confirm state, the user can edit the grid and define the real quantity and the real location of the items defined in the inventory.

When pressing the close button, all item included in the inventory are analyzed and only the ones having a "delta quantity" (i.e. real quantity - availability quantity currently defined in the warehouse) different from zero are considered: for these ones a set of correction movements is generated, in order to align the warehouse availabilities with the ones defined in the just closed inventory.

After this step, warehouse movements are allowed again.

When an inventory is in confirm state, the web application JAllInOneWeb Mobile can be used in order to define the real quantity and location for items defined in the inventory (and also for the ones not reported in the inventory); this task can be accomplished by means of the "Inventory" functionality provided by JAllInOneWeb Mobile web application: a user can use it inside a warehouse through a mobile device, such as a PDAs with a barcode reader.